3.3kW / 4.995kWp Solar Inverter Installation – Lekki, Lagos State (november 2025)

Bravestone Energy Solutions installed a 3.3kW / 4.995kWp solar power system for a frozen food outlet in Lekki, Lagos State. The system powers all lighting points and three deep freezers, ensuring uninterrupted operation for the business.

Our 3.3kw design included ample PV for daytime offset, lithium storage to smooth transitions and cover shift changes, and an AVR layer to keep sensitive control electronics within safe voltage bands. We produced a clear method statement and safety plan, then coordinated installation hours around production so the factory stayed productive.

Client:

Location: Lekki Lagos

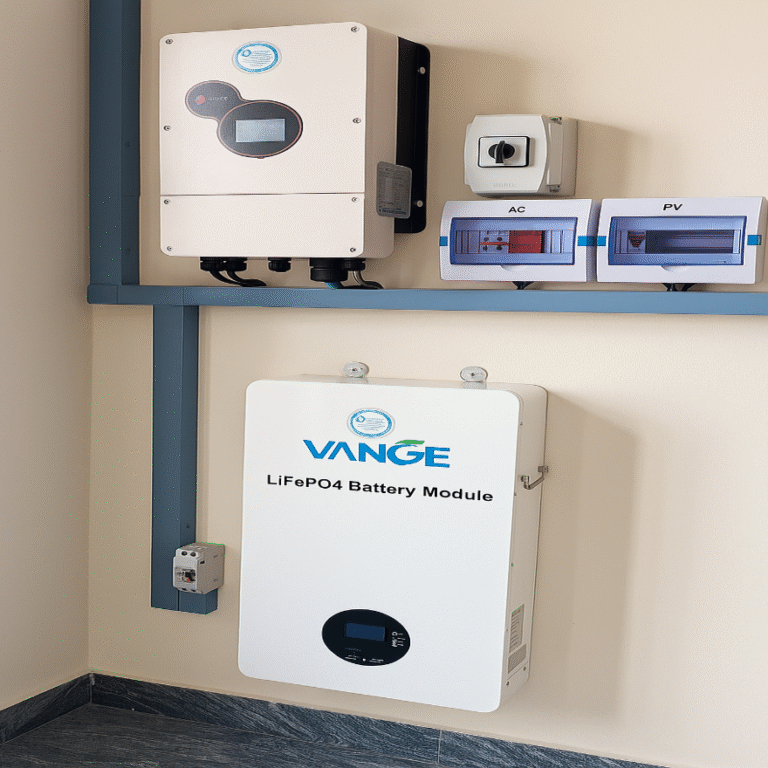

Services Industrial Survey, System Design, PV & Battery Install, Protection & Controls, Commissioning, O&M

System Specifications

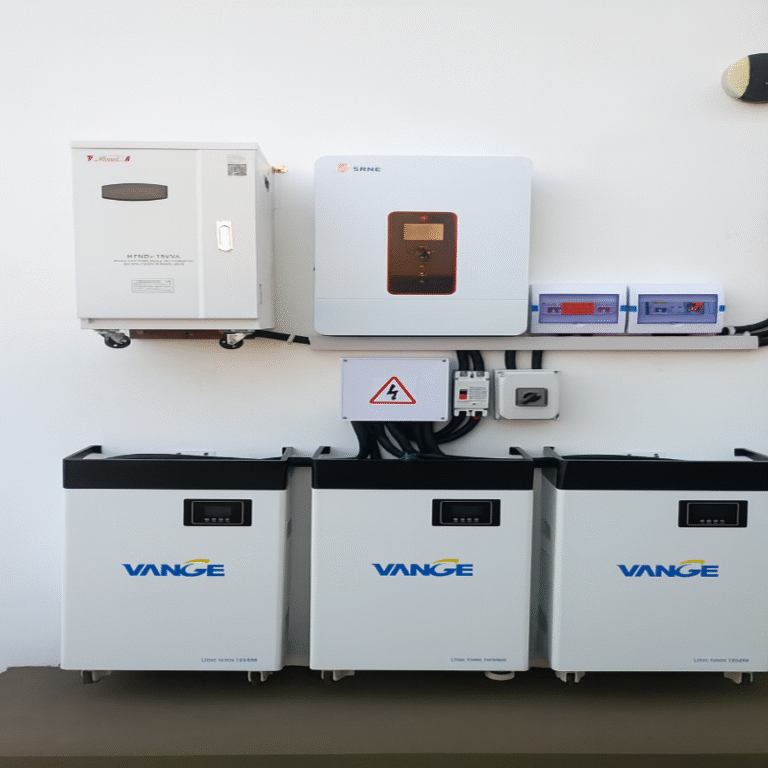

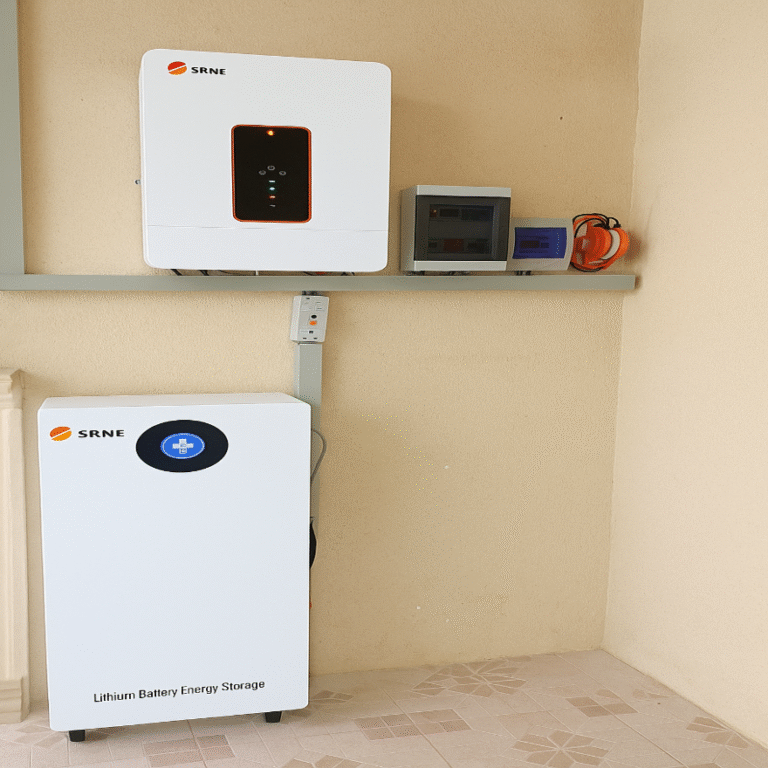

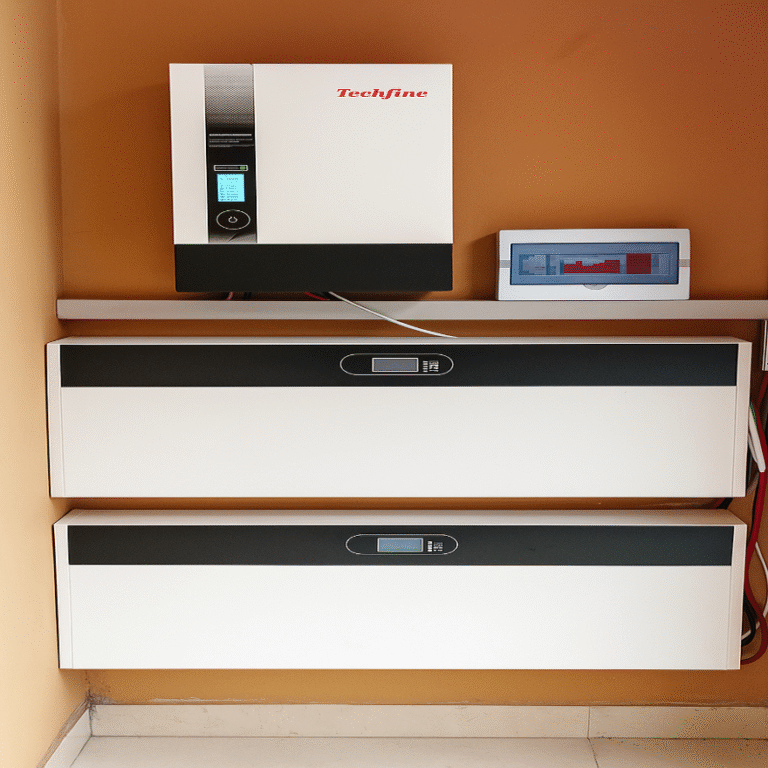

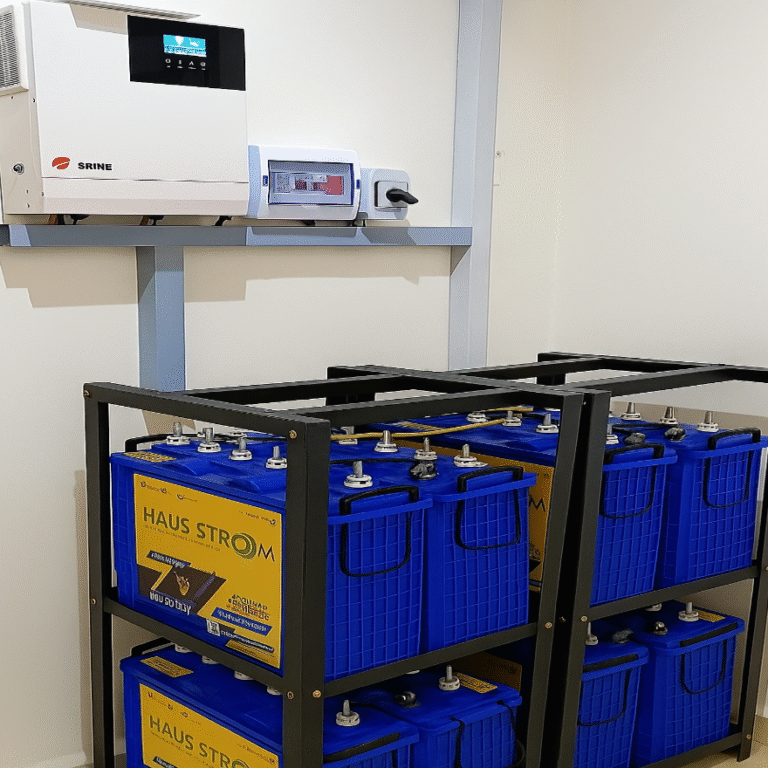

- 1 unit of 3.3kW SRNE hybrid inverter

- 1 unit of 5kWh SRNE lithium battery

- 9 units of 555W Jinko solar panels

Installation Process

Our team positioned the solar panels for maximum sunlight exposure and integrated the inverter with the outlet’s electrical setup. The battery storage ensures consistent operation during low sunlight and grid outages, keeping perishable goods safe.

Our Approach

- Survey

- Load Modeling

- Design

- HSE & Procurement

- Clean Install

- Commissioning

- Monitoring

System Size

3.3KW / ~4.9kWp

Storage

5.12kWh battery

Outage Coverage

6–8.5 hours

Diesel Reduction

≈50–65%

Install Timeline

1 days

Results & Impact

Production stability: Sequenced starts and voltage regulation reduce brownouts and stoppages.

Fuel/OPEX drop: ~50–65% reduction in generator runtime and associated costs.

Equipment protection: AVR layer and surge protection safeguard control electronics.

Workplace efficiency: Smoother restarts after grid events; better shift transitions.

Estimated solar yield: ~144–180 kWh/day (seasonal).

CO₂ avoided: ~12 t/year (indicative).

Operator empowerment: Supervisors trained on dashboards and simple response playbooks.

Service plan: Quarterly PM (thermal scans, torque checks, cleaning, firmware updates).

- Sustainability– Lowers grid dependence and reduces carbon emissions.

- Cost Savings– Decreases energy costs through efficient solar generation.

- Reliable Power Supply– Ensures uninterrupted operation of essential and comfort appliances.

- Sustainability– Reduced dependence on the grid while cutting carbon emissions.

- Cost Savings– Lower energy costs through efficient solar generation.

Reliable Power Supply – Continuous power for lighting and freezers, critical for frozen food preservation.

In Last 5 Years

& Workers With Us

Years Of Experience In

The Solar Industry

Customers Doing it Their Way!