150kW / 88.56kWp Off-Grid Solar Power Installation – Victoria Island, Lagos State (March 2025)

Bravestone Energy Solutions executed a large-scale off-grid solar power project for a six-storey office complex in Victoria Island, Lagos State. The system powers critical infrastructure including servers, lighting points, laptops, a gym, and three industrial air conditioning systems, delivering uninterrupted and sustainable electricity for business operations.

Client:

Location: VI Lagos

Services Industrial Survey, System Design, PV & Battery Install, Protection & Controls, Commissioning, O&M

System Specifications

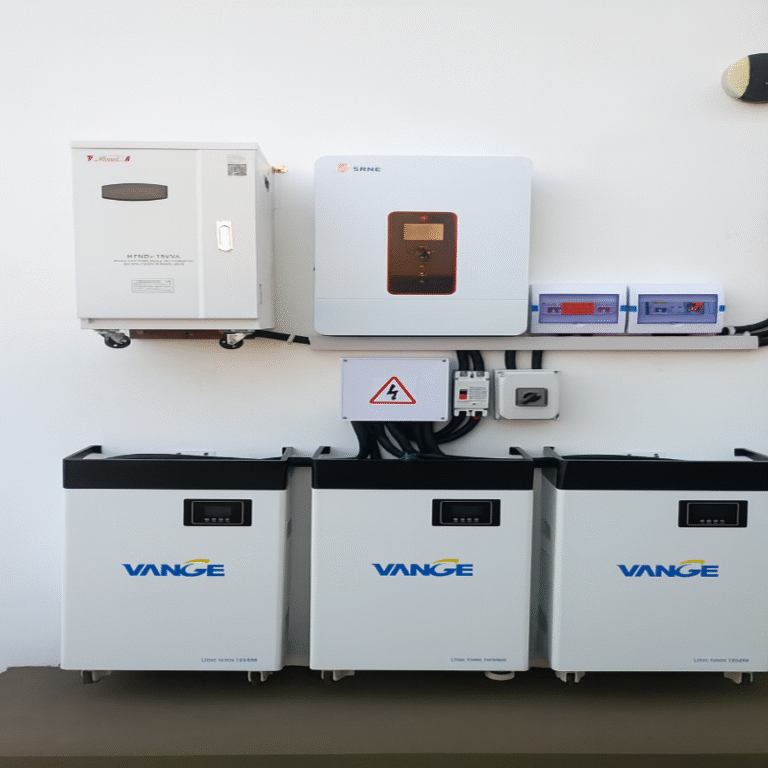

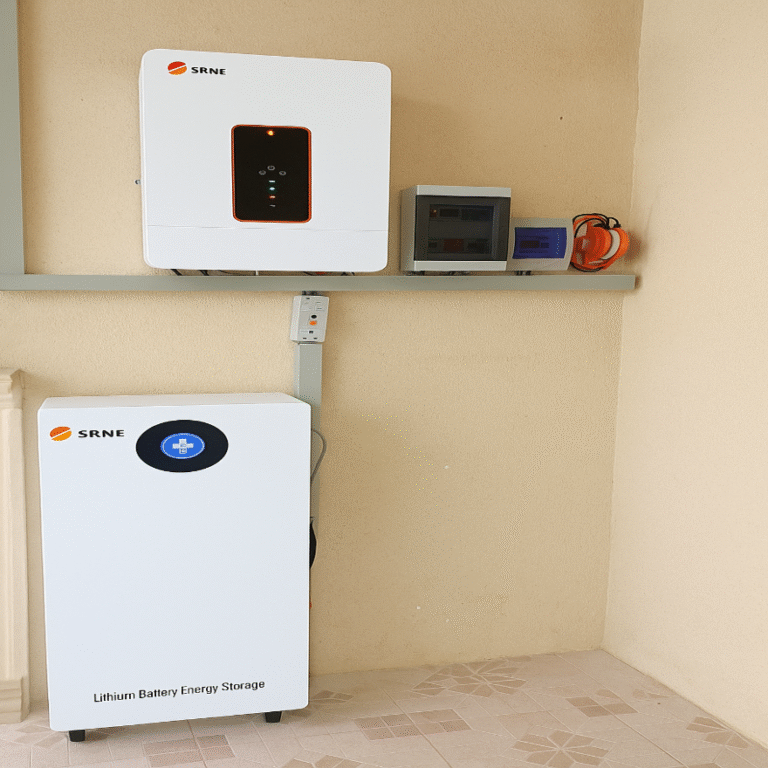

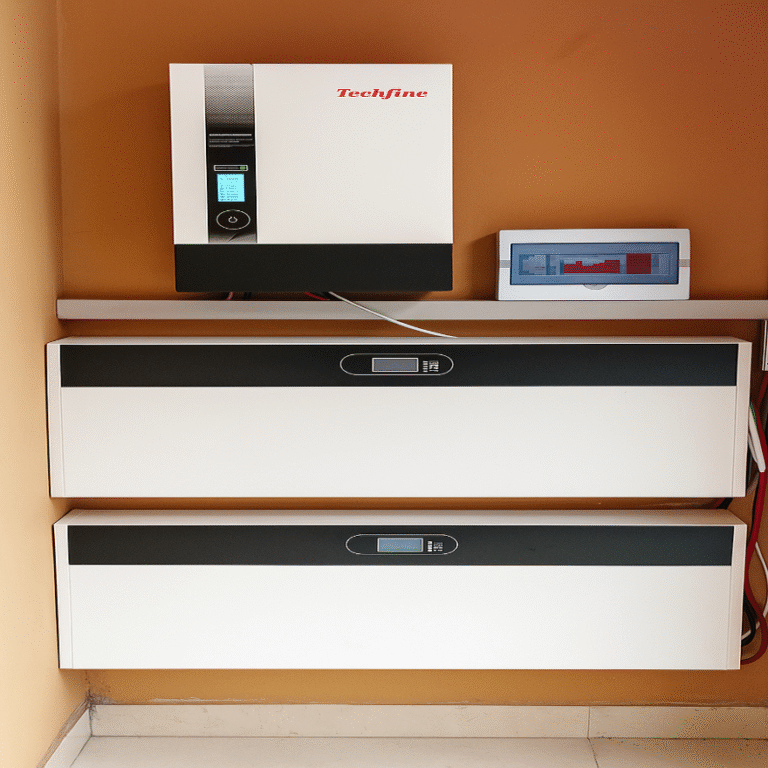

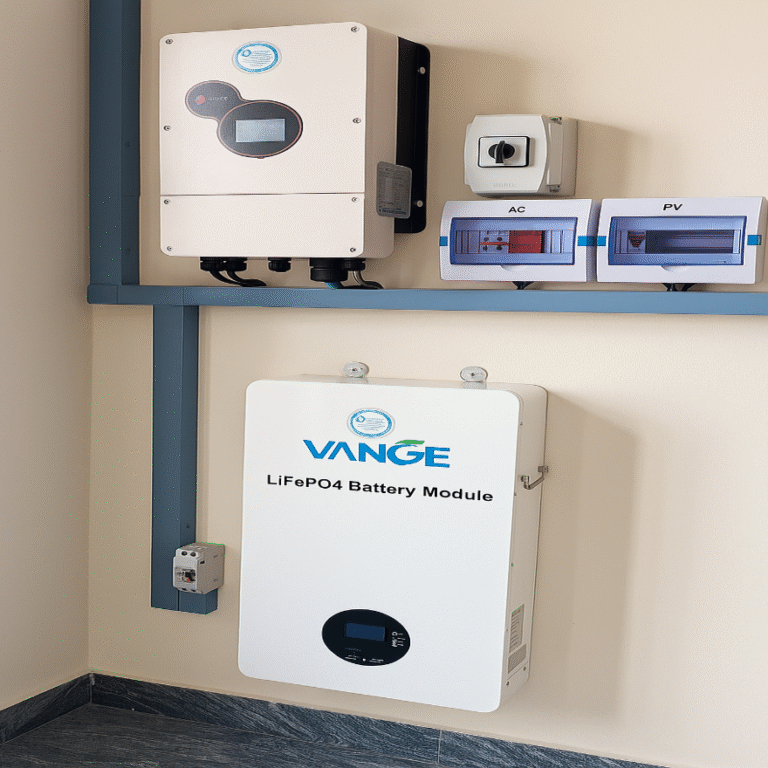

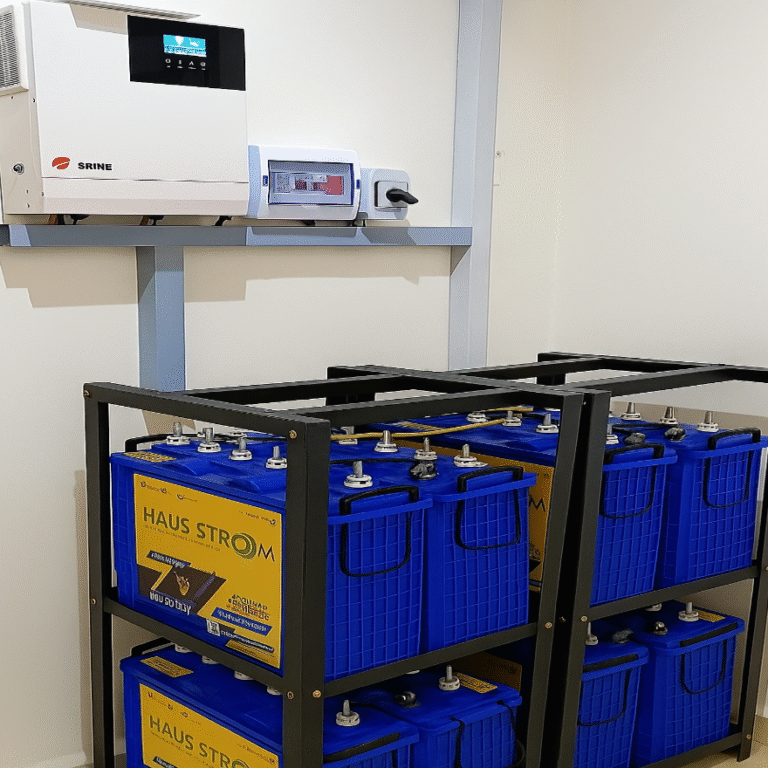

- 3 × 50kW Deye hybrid inverters

- 3 × 51kWh Galaxy Solar high-voltage lithium batteries (153kWh total storage)

- 144 × 615W Jinko solar panels

Installation Process

- High-efficiency bifacial panels installed to maximize solar energy harvest

- Hybrid inverters configured for full off-grid operation and seamless load management

High-voltage lithium battery bank deployed for extended, stable power supply to critical systems

On the roof, we built robust sub-arrays with correct spacing for heat dissipation and access. DC cabling was run in UV-stable trunking with safe drip loops, and all junctions were labelled. Inside, we installed the inverter, battery stacks, protection panels, and a dedicated maintenance clearance zone. We reworked earthing to reduce impedance and implemented surge protection at strategic points in the system.

Commissioning involved line-by-line checks: DC strings, AC boards, breaker discrimination, and staged load tests. We also programmed delayed starts for the biggest machines so the system could ramp without stress. Supervisors received training on the monitoring dashboard and a simple “what-to-do” guide for shift leads.

Results were immediate: fewer brownouts, smoother machine starts, and a noticeable reduction in fuel runs. The client enrolled in quarterly preventive maintenance—thermal scans on boards, torque checks on terminals, firmware updates, and dust management for panels and power rooms—protecting output over the long term.

Our Approach

- Survey

- Load Modeling

- Design

- HSE & Procurement

- Clean Install

- Commissioning

- Monitoring

System Size

150kVA / ~90kWp

Storage

153kWh battery

Outage Coverage

18 hours

Diesel Reduction

≈50–65%

Install Timeline

7 days & ~12 t/yr

Results & Impact

Production stability: Sequenced starts and voltage regulation reduce brownouts and stoppages.

Fuel/OPEX drop: ~50–65% reduction in generator runtime and associated costs.

Equipment protection: AVR layer and surge protection safeguard control electronics.

Workplace efficiency: Smoother restarts after grid events; better shift transitions.

Estimated solar yield: ~144–180 kWh/day (seasonal).

CO₂ avoided: ~12 t/year (indicative).

Operator empowerment: Supervisors trained on dashboards and simple response playbooks.

Service plan: Quarterly PM (thermal scans, torque checks, cleaning, firmware updates).

- Business Continuity – Reliable off-grid power eliminates downtime from grid interruptions

- Energy Efficiency – Optimized solar generation reduces long-term operating costs

- Sustainable Operations – Cuts carbon footprint while meeting demanding commercial energy needs

In Last 5 Years

& Workers With Us

Years Of Experience In

The Solar Industry

Customers Doing it Their Way!